Sintered Neodymium Magnets

Product name : Sintered Neodymium Magnets

Model No. : GMG1-N

Products Category: > Neodymium Permanent Magnets

In 1984, Sagawa, Hadjipanayis and Croat independently discovered Neodymium magnet nearly at the same time. The main phase of Neodymium magnet is Nd2Fe14B and maximum energy products achieved 280kJ/m3 at that time. The successful development of Neodymium magnet announced the birth of the third-generation rare earth permanent magnet. Neodymium magnet also referred as NdFeB magnet because they are composed primarily of Neodymium (Nd), Iron (Fe), and Boron (B). Neodymium magnet can be classified to sintered Neodymium magnet, Bonded Neodymium magnet, and hot-pressed Neodymium magnet according to the detailed manufacturing process. Sintered Neodymium magnet still offers the strongest magnetic power nowadays and has been widely served to vast kinds of application, include high-performance permanent motors, brushless DC motors, magnetic separators, magnetic resonance imaging (MRI), sensors,loudspeakers, consumer electronics, and green energy.

▲ Manufacturing Process of Sintered Neodymium Magnet:

● Introduction of manufacturing process:

Sintered Neodymium magnet is prepared by the raw materials being melted under vacuum or inert gas atmosphere in an induction melting furnace and processed in the strip caster and thus cooled to form alloy strip. The strips are crushed and pulverized to form a fine powder ranging from 3 to 7 microns in particle size. The powder is subsequently compacted in an aligning field and sintered into dense bodies. The blanks are then machined to the specific shapes, surface treated and magnetized.

● Process Steps of Sintered Neodymium Magnet:

-1673841.jpg)

▲ Magnetic Properties of Sintered Neodymium Magnet:

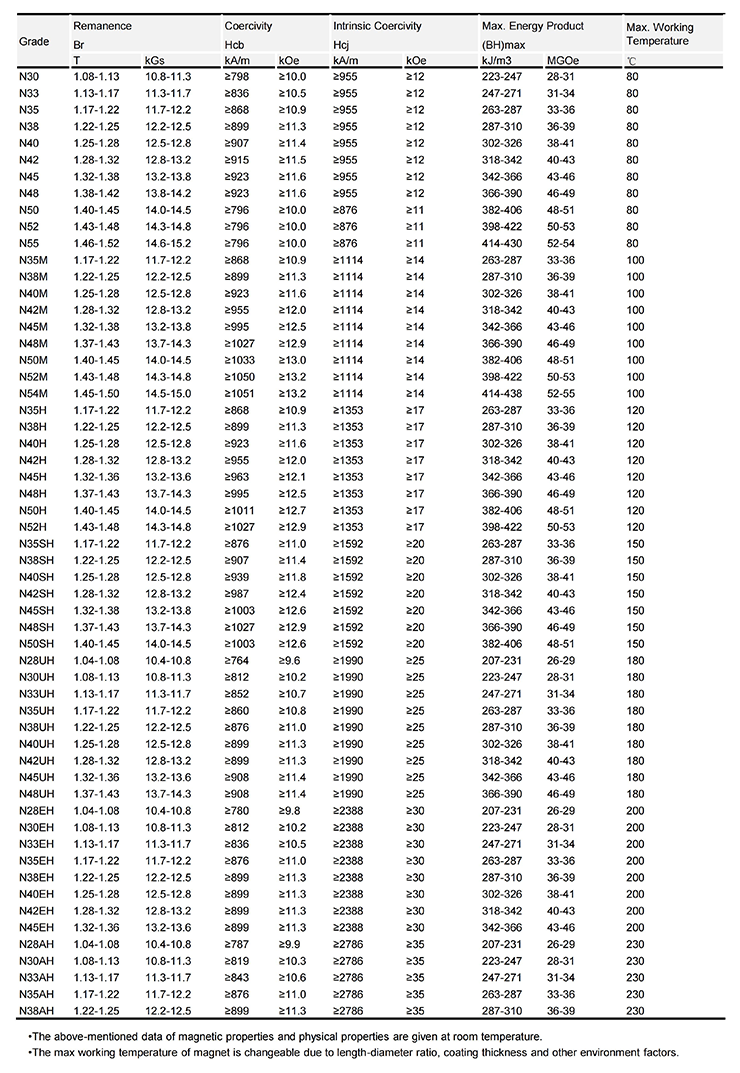

● Grade of Sintered Neodymium Magnet:

The grades of sintered Neodymium magnet are generally specified by letter N+number+letter. The letter N is the abbreviation and stand for Neodymium. The number that follows represent the maximum energy product of the magnet in CGS unit “Mega-Gauss Oersted” (MOGe). There are on or two letters tagged on the end termine the intrinsic coercivity and maximum operating temperature of the sintered Neodymium magnet. Instrinsic coercivity of M (Middle), H (High), SH (Super High), UH (ultra high), EH (extreme high), and AH (abnormal high) grade are greater than 14, 17, 20, 25, 30, 35kOe, respectively. The their maximum operating temperature can reach 100, 120, 150, 180, 200 and 230 degree Celsius separately. It should be noted that there are some grades without last letters, especially the best well-known N35 and N52. Intrinsic coercivity of these grades is higher than 12kOe and maximum operating temperature should be less than 80 degrees Celsius.

● Magnetic Properties Chart of Sintered Neodymium Magnet:

● Other Magnetic Properties of Sintered Neodymium Magnet:

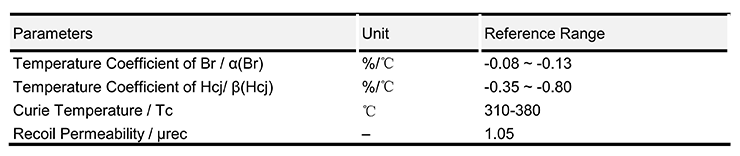

▲ Physical Properties of Sintered Neodymium Magnet:

● Introduction of Physical Properties:

In addition to permanent magnetic properties and corrosion resistance, working stability of sintered Neodymium magnet is strongly tied to its own physical properties. Besides regular density and hardness, physical properties of sintered Neodymium magnet also covered machanical properties, electrical properties, and thermal properties. Mechanical properties are primarily measured by compressive strength, tensile strength, and bending strength. These three metrics have considerable influence on the machinability and long-term performance of instered Neodymium magnet. Electrial properties of metallic material are measured by electrical resistivity. Sintered Neodymium magnets possess relatively lower electrical resistivity and vulnerable to eddy current loss when applied to rotary machinery. Thermal properties of sintered Neodymium magnet are usually characterized by coefficient of thermal expansion. Thermal expansion of sinstered Neodymium magnet wil certainly lead to dimension change, then magnets in the magnetic device will generate a certain of stress due to such dimension change if the expansion difference between magnets and assembly material relatively large, and thus cause mechanical damages and magnetic performance deteriorations.

● Physical Properties Chart of Sintered Neodymium Magnet:

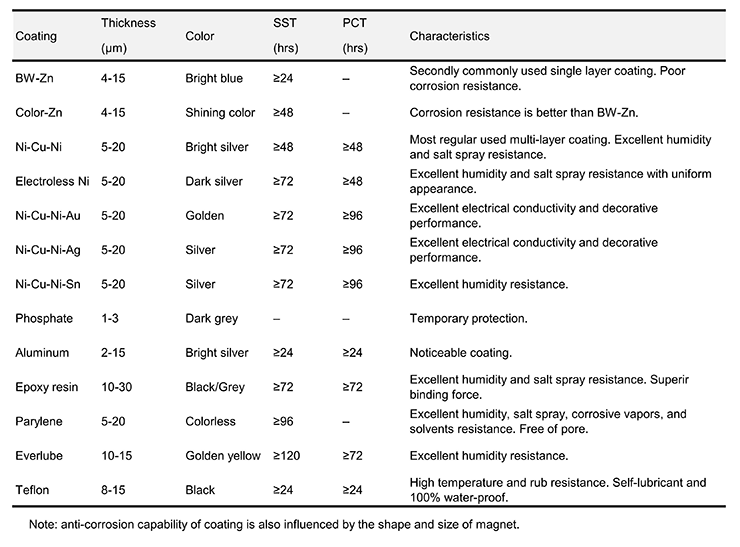

▲ Surface Treatment Classification of Sintered Neodymium Magnet:

● Introduction of Surface Treatment:

SmCo Series Magnet with Cobalt as main component has superior chemical stability, therefore, Samarium Cobalt magnets are qualified for most applications without any surface treatment. Surface protective treatment is the necessary procedure for the Neodymium magnet, especially sintered Neodymium manet. Nd-rich phase possesses very strong oxidation tendency and will constitute the primary battery with Nd2Fe14B main phase under humid condition. Subsequently, Nd-rich phase is corroded and main phase particle peeled from the magnet body gradually. Surfance protective treatment of sintered Neodymium magnet is primarily classified into wet process and dry process. The frequently-used wet process includes electroplating, electrolessplating, electrophoresis, spray coating, and dip coating. Dry process generally contains physical vapor deposition (PVD) and chemical vapor deposition (CVD).

● Surface Treatment Classifications of Sintered Neodymium Magnet:

▲ Magnetization Direction of Sintered Neodymium Magnet:

● Introduction of Magnetization Process:

Magnetization process refers to apply magnetic field along the specific direction of the permanent magnet, then gradually increasing magnetic field strength to saturate the magnet. Permanent magnet normally needs to be magnetized prior to being served for intending applications. Different permanent magnet requires distinct magnetic field strength to achieve technical saturation. As a type of anisotropic magnet, sintered Neodymium magnet has a preferred direction of magnetization and various pole configurations can be realized as long as not conflicting with the magnet’s orientation.

● Magnetization Patterns of Sintered Neodymium Magnet:

-7541777.png)

▲ Shape Categories of Sintered Neodymium Magnet:

-7294996.png)

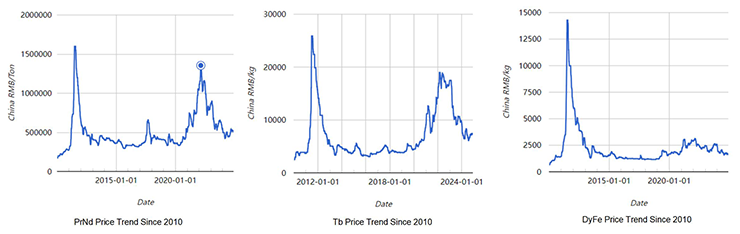

▲ Influencing Factors of Sintered Neodymium Magnet Price:

Raw material cost occupy the largest proportion in the whole magnet cost. As a primary raw material, the content of PrNd mischmetal in sintered Neodymium magnet is around 30wt%. Fluctuations of PrNd price trend have the most direct influence on the sintered Neodymium magnet price. Heavy rare earth elements (HREEs) Dysprosium (Dy) and Terbium (Tb) are typically used in the form of DyFe alloy and Tb metal. Either Dy or Tb can significantly enhance intrinsic coercivity Hcj of sintered Neodymium magnet, but the cost is sharply increasing at the same time. Thereby, HREEs-less and HREEs-free solutoin like grain boundary diffusion (GBD) technology have introduced to reduce HREEs use.

---The End---

Send Inquiry :

Products Category

Featured Products

Contact Us

Name: April Yang

Tel: 0086-1560-1120-906

E-mail: [email protected]

Add: No. 18, Sihai Road, BDA, Beijing, China

Whatsapp: 0086 1560 1120 906

Wechat: 0086 1560 1120 906

QQ: 1013104078