Samarium Cobalt Magnets

Product name : Samarium Cobalt Magnets

Model No. : GMG1-S

Products Category: > Samarium Cobalt Magnets

1:5 type and 2:17 type sintered Samarium Cobalt magnet is referred as the first generation and second generation of rare earth permanent magnet. Sintered Neodymium magnets ruled rare earth permanent magnet market since its inception, therefore, Samarium Cobalt magnet is marginalized seriously as a result of relatively lower magnetic properties, complex processing technologies, and costs. But in reality, sintered Samarium Cobalt magnetic is still playing an irreplaceable role in high-temperature applications which are not possible for sintered Neodymium magnet. The research of high-performance sintered Samarium Cobalt magnet has never ceased, then complex multistage heating treatment and microstructure control effectively enhanced magnetic performance to an extreme level. In order to fulfill the new application in aerospace area, United States Department of Defense demanded that improve the maximum operating temperature of sintered Samarium Cobalt magnet to the 500 degrees Celsius from 300 degrees Celsius in 1997. In the meanwhile, some higher high-end applications like travelling wave tube and internal device also asked reversible temperature coefficient of sintered Samarium Cobalt magnets should have small enough absolute value. Therefore, TbCu7-type structure Sm2Co7-Based magnets emerged and gained widely concern.

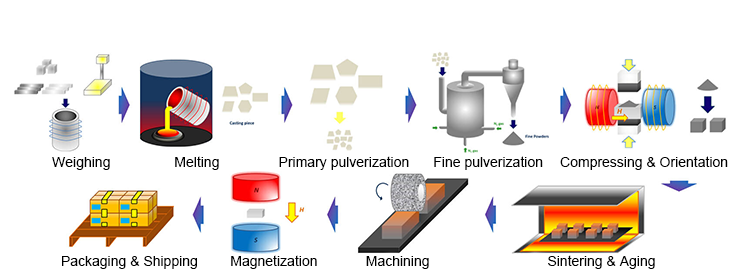

▲ Manufacturing Process of Sintered Samarium Cobalt Magnet:

● Introduction of Manufacturing Process:

Sintered Samarium Cobalt magnet is prepared by the raw materials being melted under vacuum or inert gas atmosphere in an induction melting furnace and processed in the strip caster and thus cooled to form alloy strip. The alloys are crushed and pulverized to form a fine powder with an average particle size of 3 microns. The powder is subsequently compacted in an aligning field. Densification and the adjustment of magnetic properties are accomplished via sinter, solution and aging processes. The blanks are then machined to the specific shapes and magnetized.

● Process Steps of Sintered Samarium Cobalt Magnet:

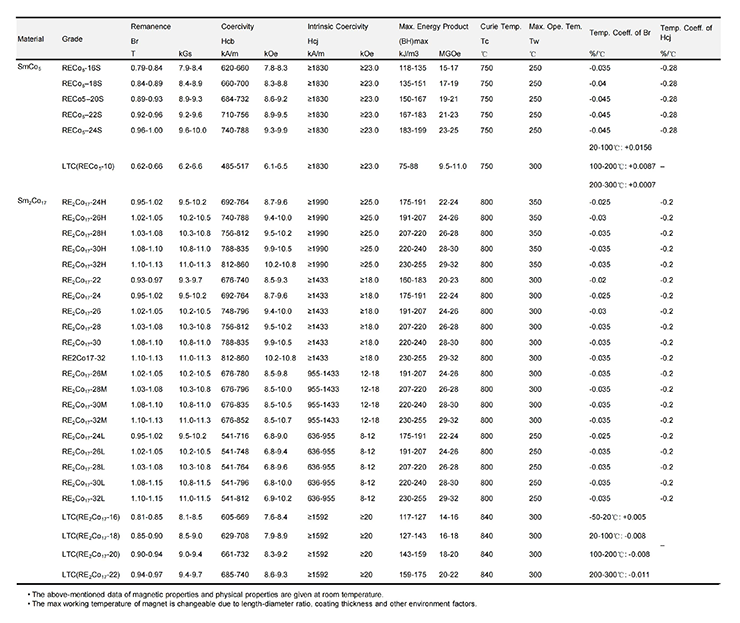

▲ Magnetic Properties of Sintered Samarium Cobalt Magnet:

● Grade of Sintered Samarium Cobalt Magnet:

The grades of sintered Samarium Cobalt magnet are typically specified by alloy composition +number +letter. Samarium Cobalt magnet can be divided into SmCo5 (REC05) based and Sm2Co17 (RE2Co17) based according to alloy composition. The latter number represents that the maximum energy product (BH) max of the magnet in CGS unit “Mega-Gauss Oersted” (MGOe). There is no or one letter tagged on the end of determine the intrinsic coercivity of the sintered Samarium Cobalt magnet.

● Magnetic Properties Chart of Sintered Samarium Cobalt Magnet:

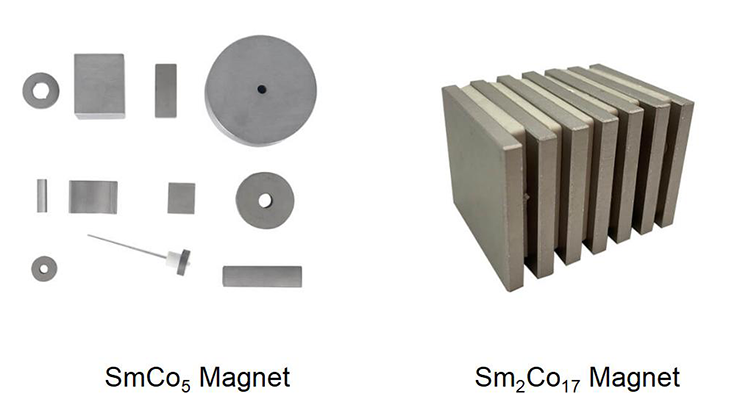

▲ Classifications of Samarium Cobalt Magnet:

Samarium Cobalt magnet, also referred to as SmCo magnet, is produced by traditional powder metallurgy process and can be classified into SmCo5 and Sm2Co17 based according to alloy composition. SmCo5 and Sm2Co17 are normally referred as the first and second generation of rare earth permanent magnetic material, respectively.

● SmCo5 Magnets:

(BH) max values of regular SmCo5 magnet are between 14 and 24MGOe. SmCo5 is made of only Samarium and Cobalt and exhibit better corrosion resistance and machinability.

● Sm2Co17 Magnets:

(BH) max values of conventional Sm2Co17 magnet are between 22 and 32MGOe which much higher than the former SmCo5 series. Besides two basic elements Samarium and Cobalt, different grade of Sm2Co17 varies in the content of Iron (Fe), Copper (Cu), Zirconium (Zr).

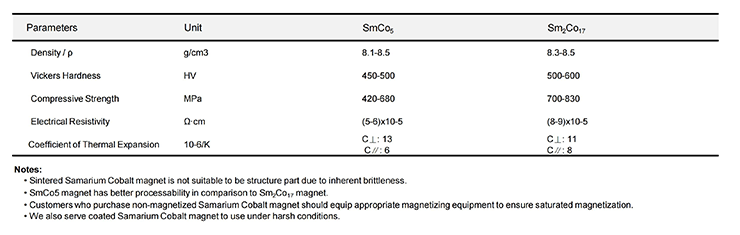

▲ Physical Properties of Sintered Samarium Cobalt Magnet:

▲ Shape Categories of Sintered Samarium Cobalt Magnet:

▲ Influencing Factors of Sintered Samarium Cobalt Magnet Price:

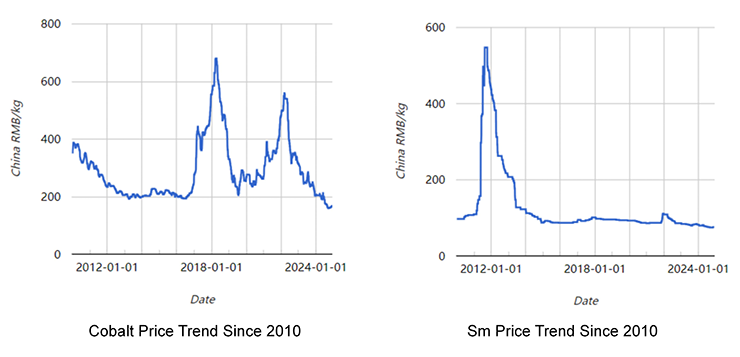

Samarium Cobalt magnet is primarily composed of Samarium (Sm) and Cobalt (Co). SmCo5-type and Sm2Co17-type magnet typically contains 23-28wt% and 33-37wt% Samarium, respectively. Sm price trends is extraordinary stable in the past few yeras and has very limited impact on the sintered Samarium Cobalt magnet price. Cobalt content in SmCo5-type and Sm2Co17-type MAGNET REACHED 63-67wt% AND 48-52wt%, respectively. Unlike AlNiCo magnet, Samarium Cobalt magnet adopts primary Cobalt as raw material. Fluctuations of Cobalt price trend has the most visible influence on the sintered Samarium Cobalt magnet.

---The End---

Send Inquiry :

Products Category

Featured Products

Contact Us

Name: April Yang

Tel: 0086-1560-1120-906

E-mail: [email protected]

Add: No. 18, Sihai Road, BDA, Beijing, China

Whatsapp: 0086 1560 1120 906

Wechat: 0086 1560 1120 906

QQ: 1013104078