Ferrite Magnets

Ferrite magnet, otherwise referred as ceramic magnet or hard ferrite, is developed by Japanese scholars Dr. Yogoro Kate and Dr. Takeshi Takei in 1930. As nonmetallic type of permanent magnet material, ferrite magnet is utilizing iron oxide (Fe2O3), Barium Carbonate (BaCo3) or Strontium Carbonate (SrCo3) as raw material, therefore, ferrite magnets can be classified to Strontium ferrite magnets and Barium ferrite magnets according to the composition. Strontium ferrite magnets and Barium are also known as anisotropic ferrite magnets and isotropic ferrite magnets, respectively. In addition to superior cost advantage and corrosion resistance, ferrite magnets are medium in magnetic properties and can be applied under relatively high temperature conditions.

▲ Classifications of Ferrite Magnets

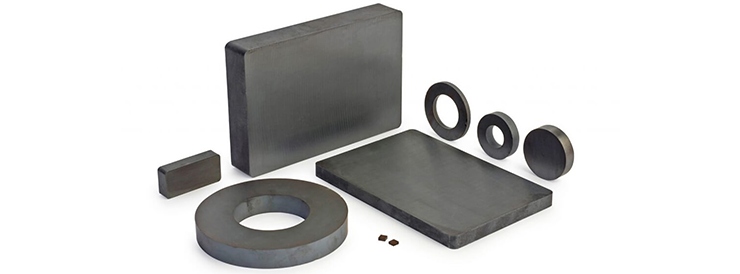

Ferrite magnets can be divided into sintered ferrite magnets and bonded ferrite magnets according to the manufacturing process. Sintered and boned form has their distinctive magnetic performance and application scope.

○ Sintered Ferrite Magnets

Sintered ferrite magnets are widely served for the various walks of life in the past several decades and still possess very large market share of permanent magnets nowadays.

Ferrite magnet, otherwise referred as ceramic magnet, is developed by Jananese scholars Dr. Yogoro Kate and Dr. Takeshi Takei in 1930. As nonmetallic type of permanent magnetic material, ferrite magnet is utilizing iron oxide (Fe2O3), Barium Carbonate (BaCo3) or Strontium Carbonate (SrCo3) as raw material and then manufactured through ceramics process. Maximum operating temperature of sintered ferrite magnet can arrive 250 degrees Celsius. Sintered ferrite magnet also has superior corrosion resistance. Sintered ferrite magnet is generally used in various areas in the past several decades and its market share is still very large even the application range of sintered Neodymium magnets is more and more extensive. The most representative applications of sintered ferrite magnet include loud speakers, permanent magnet (PM) motors and generators.

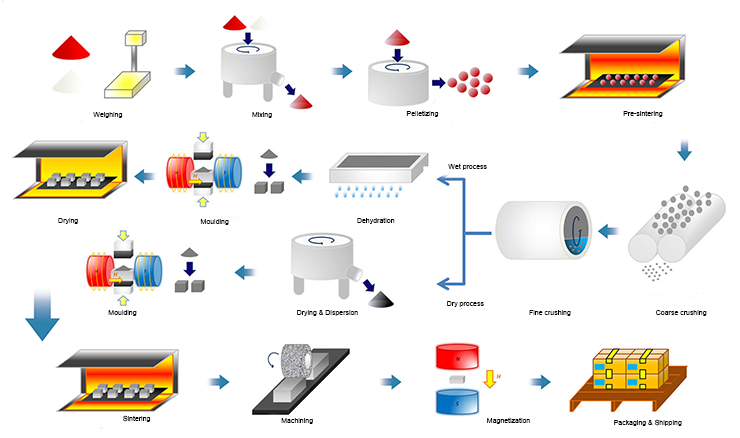

● Manufacturing Process of Sintered Ferrite Magnet

● Magnetic Properties of Sintered Ferrite Magnet

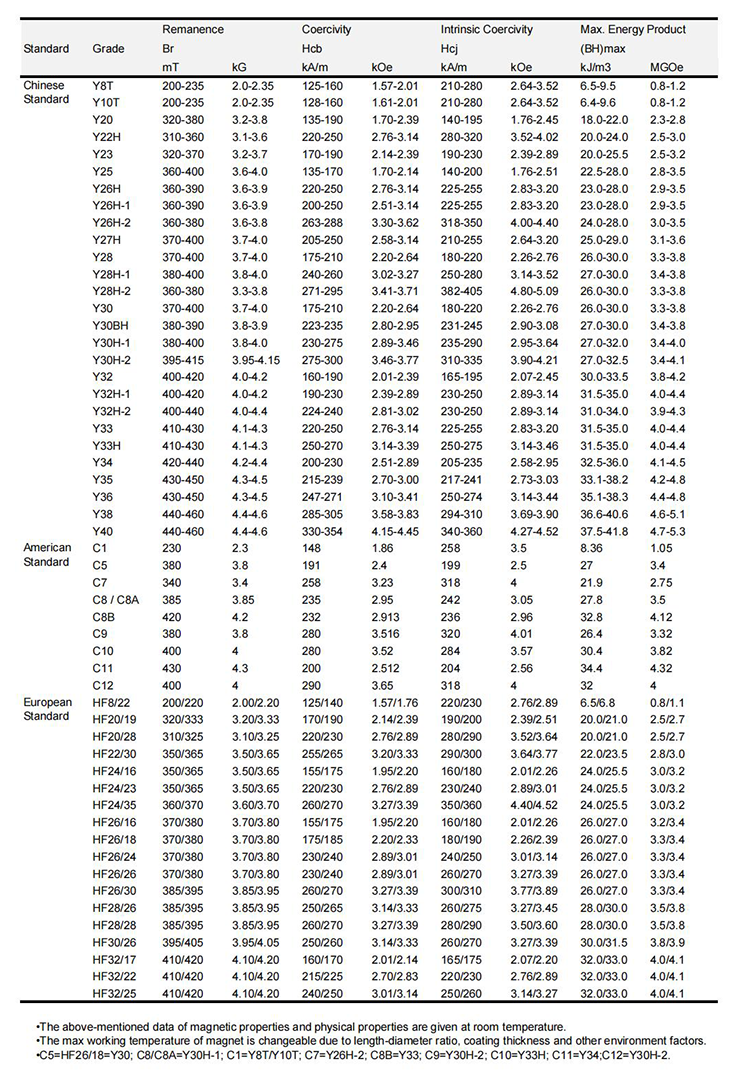

◆ Grade of Sintered Ferrite Magnet

There are three standards for the grade of sintered ferrite magnet: United States Industry Standard, International Electrotechnical Commission Standard, and Chinese Standard. International Electrotechnical Commission Standard is confined to European. The grade is made up of the minimum value of the maximum energy product in SI unit “kJ/m3” and intrinsic coercivity in SI unit “kA/m”. For United Stated Industry Standard, grade of sintered ferrit magnet is generally labelled with the letter “C” and a number, such as C5 and C8. Since most production of sintered ferrite magnet is in China, Chinese nomenclature system has taken over the naming right of grade. All grades beginning with the letter “Y” which is an identifier for sintered ferrite magnet. The number following it represent the maximum energy product and any letter after the number is an additional identifier.

◆ Magnetic Properties Chart of Sintered Ferrite Magnet

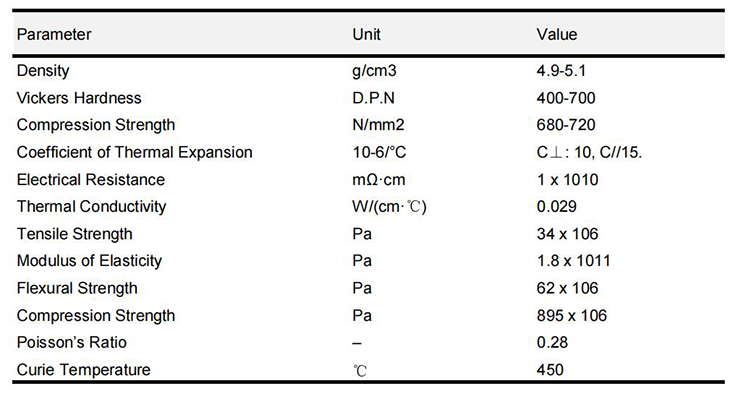

● Physical Properties of Sintered Ferrite Magnet

◆ Introduction of Physical Properties

Working stability of sintered ferrit magnet is strongly tied to their physical properties except magnetic properties. Sintered ferrite magnet is extremely prone to chipping or breaking owing to inherent brittleness.

◆ Physical Properties Chart of Sintered Ferrite Magnet

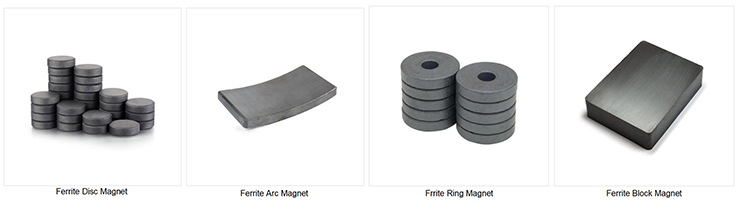

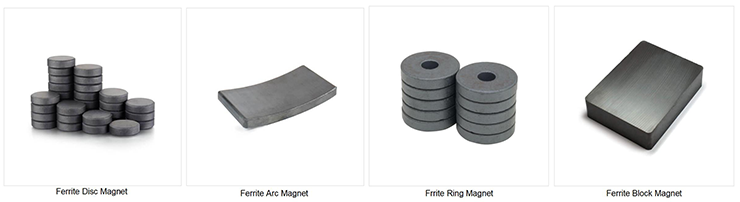

● Shape Categories of Sintered Ferrite Magnet

◇ Bonded Ferrite Mangets

Bonded ferrite magnets can be further classified to injection ferrite magnets, extruded ferrite magnets, and calendered ferrite magnets base on the binder type and molding process. The latter two magnets are collectively known as the rubber magnet.

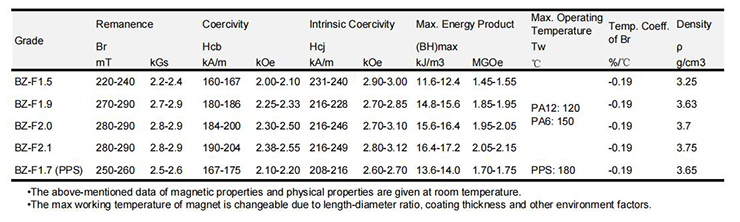

◇ Injection Ferrite Magnet

Injection ferrite magnet is a type of bonded magnet manufactured by mixing ferrite magnetic powder with the thermoplastic binder which then enables the magnet to be injection molded just like any other plastic would be. The maximum operating temperature of PA12 based, PA6 based, and PPS based magnet can achieve 120, 150, and 180 degrees Celsius, respectively. Injection ferrite magnet also has excellent mechanical strength, dimensional accuracy, shape applicability, and integrated ability with other functional parts, which totally same as injection molded Neodymium magnet. Its magnetic performance and cost is significantly lower than injection molded Neodymium magnet and widely served for sensors and low performance motors. Anisotropic injection ferrite magnet need to apply a permanent magnetic field or an electromagnetic field to align molten compound during the injection molding process.

● Magnetic Properties of Injection Ferrite Magnet

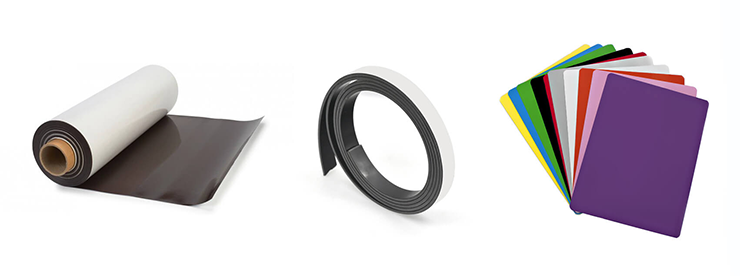

○ Rubber Magnets

Rubber magnet, also referred as flexible magnet, is a type of magnet made by blending ferrite magnetic powder with rubber which is then calendered to produce strip, sheet, or roll. Bonded magnet Bonded magnet can be divided into compression molded magnet, injection molded magnet, extruded magnet, and calendered magnet base on processing technology. Rubber magnet is belonging to the calendered magnet. Rubber magnets can be easily produced into all kinds of shapes and sized from a few millimeters to tens of meters owing to exceptional elasticity, flexibility, and machinability. Conventional post processing includes blanking, cut-off, punching, and bending.

Rubber magnet is generally laminated by colorful PVC, adhesive tape, or polychrome printing. Fridge magnet is undoubtedly the most representative application of rubber magnet. Fridge magnet is often utilized to post items or served as decoration. Fridge magnets can be provided in a wide variety of shapes and sizes, therefore, many people treat them as a popular souvenir and collectible objects. Due to the limitations of low magnetic performance, axially multipole magnetization applies to enhance the pull force of fridge magnets.

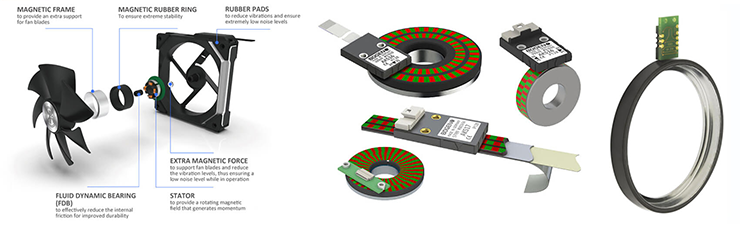

Flexible magnet is widely served for either civilian uses and industrial applications. Ring magnet wounded by axially multipole magnetized magnetic strip is much easier to realize ultra multipole magnetization compared with whole ring magnet, then enable it to serve for fan motors and the vast majority of linear or rotary magnetic encoder. In addition to the frequently-used ferrite based magnet. Fe3B based magnet with have high Br and low Hcj is also available.

▲ Shape Categories of Ferrite Magnet

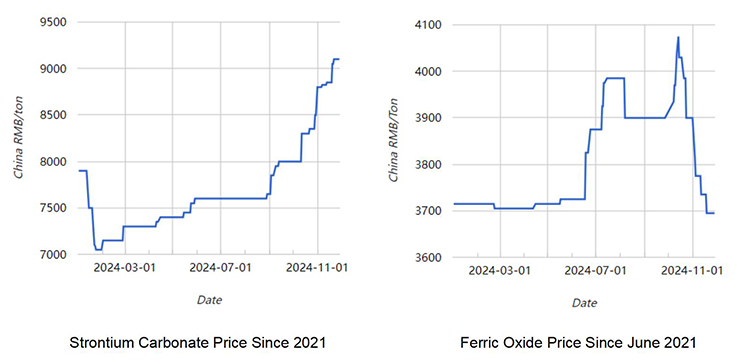

▲ Influencing Factors of Ferrite Magnet Price

The main raw material of ferrite magnet includes Strontium Carbonate and iron oxide. Ferrite magnet price will also fluctuate with the price change of these raw materials. Strontium Carbonate and the source of iron oxide are occupying 85% and 15% of the entire material cost, respectively. Therefore, it is self-evident that the price index of Strontium Carbonate has decisively impact on the ferrite magnet price. Ferrite magnet with different levels, formulas, and process technology has its unique demands on the raw material of iron oxide. For Ferrite magnets, the source of iron oxide includes preprocessed iron scale and ferric oxide which prepared via Ruthner process. Iron scale is typically referring to the scaly oxide layers which peeled off from steel during its heating or rolling process. It is necessary to preprocess iron scale to ensure magnetic properties of ferrite magnet and that’s why routine iron scale’s price cannot be chosen as the price index. As a conventional inorganic compound, price index of ferric oxide is more convincing to downstream in comparison with preprocessed iron scale.

---The End---

Send Inquiry :

Products Category

Featured Products

Contact Us

Name: April Yang

Tel: 0086-1560-1120-906

E-mail: [email protected]

Add: No. 18, Sihai Road, BDA, Beijing, China

Whatsapp: 0086 1560 1120 906

Wechat: 0086 1560 1120 906

QQ: 1013104078