AlNiCo Magnets

AlNiCo is the abbreviation of Aluminum-Nickel-Cobalt. As a member of non-rare earth metallic permanent magnetic material, AlNiCo magnet was developed by Japanese metallurgy Tokushichi Mishima in 1931 and once ruled the permanent magnet industry before the rare earth permanent magnet was emerged. AlNiCo is composed of primary Aluminum, Nickel, Cobalt, and Iron. Furthermore, minor amount alloying element Titanium, Niobium, and Copper is added to matrix phase to promote the growth of needle phase and thereby enhance coercivity. Besides commonly used areas like loudspeaker, sensor, guitar pickup, magnet chuck, or magnetic lifter, AlNiCo is still serving for some specialty application owing to its matchless temperature stability.

▲ Shape Categories of AlNiCo Magnet:

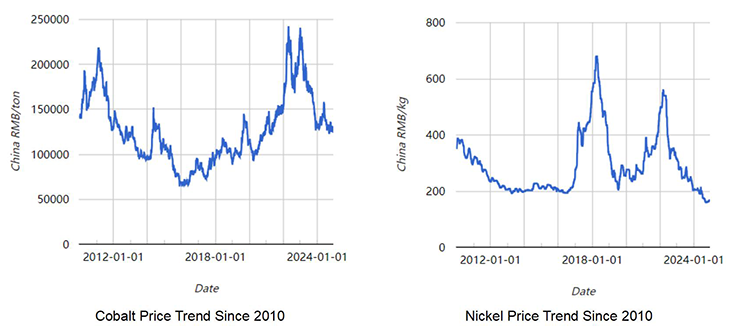

▲ Influencing Factors of AlNiCo Magnet Price:

AlNiCo magnet price is still one of the most concerned factors to users even its market share and cost are relatively low. Cobalt and Nickel content in AlNiCo ranges from 2-42wt%, and 13-28wt%, respectively. This means that Cobalt price trend and Nickel price trend have the most significantly impact on the AlNiCo magnet price. The majority of AlNiCo 8 and AlNiCo 9, most of cast magnets utilize recycled Cobalt and Nickel as raw material, so have limited demand for primary Cobalt and Nickel. Price trends of these two recycled material can basically refer to primary material’s tendencies.

▲ Cast AlNiCo Magnet vs. Sintered AlNiCo Magnet:

AlNiCo can be made by either casting or sintering process. AlNiCo grades mainly vary in Cobalt content and relevant heat treatment process. This historical permanent can be further divided to isotropic or anisotropic and grain oriented or grain non-oriented. Cast magnet is larger in density which provides it better magnetic performance. Casting process also well-suited to large and complex shapes. Sintered magnet exhibit slighter lower magnetic performance but better machanical properties.

-6296201.png)

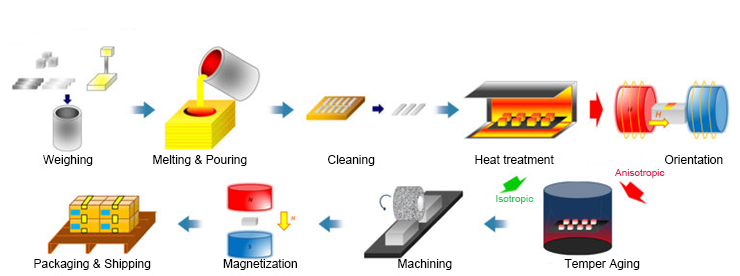

○ Cast AlNiCo Magnet:

The majority of AlNiCo magnets are belonging to cast type and AlNiCo 5 is the most frequently used grade among them. Cast AlNiCo magnet is produced by common foundry processes. Molten AlNiCo alloys with different chemical composition are melted by induction furance and poured into the resin bonded sand molds, then solidified material with a rough surface will process heat treatment and cooling process. Cast AlNiCo magnet can offer slighter higher magnetic performance in comparison with sintered AlNiCo magnet. Cast AlNiCo magnet can be divided to the isotropic form and anisotropic form base on whether apply the orientation magnet field during the cooling process. The majority of cast AlNiCo magnet are anisotropic magnet to fully enhance magnetic properties. Therefore, AlNiCo blank will be machined to exact geometry and tolerance after underwent heat treatment process.

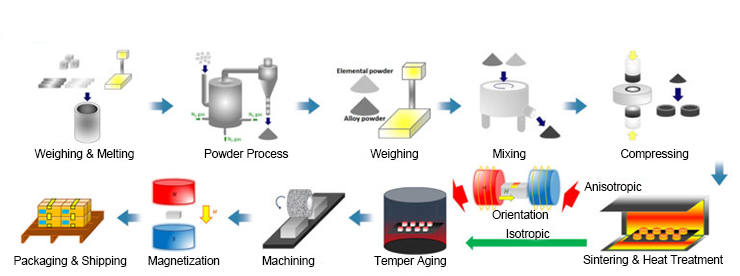

● Manufacturing Process of Cast AlNiCo Magnet

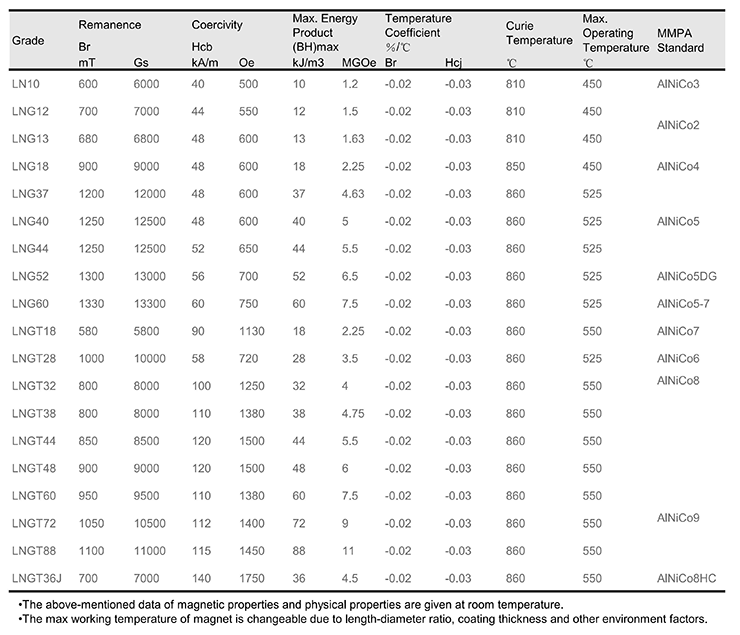

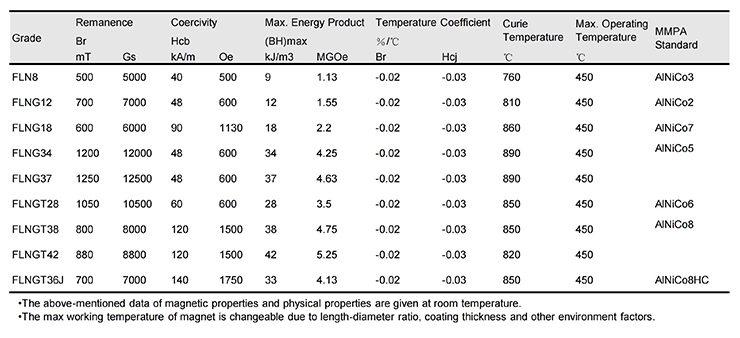

● Magnetic Properties of Cast AlNiCo Magnet

○ Sintered AlNiCo Magnet:

Sintered AlNiCo magnet is manufactured by traditional powder metallurgy technology which basically same as other sintered permanent magnets. The overall magnetic properties of sintered AlNiCo magnet are slightly lower than cast AlNiCo magnets, thus not so frequently used like the latter. Sintered AlNiCo magnets are well adapted for small sized (less that 28 grams), thin, light, and special shaped magnets. In addition to high dimensional accuracy, tight tolerance, and without further machining steps, sintered AlNiCo magnet also exhibit slightly mechanical strength and machinability. Viewing from the large volume production, sintered AlNiCo magnet has higher material utilization ratio, lower composition segregation, and magnetic performance fluctuation in comparison with cast AlNiCo magnet.

● Manufacturing Process of Sintered AlNiCo Magnet:

● Magnetic properties of Sintered AlNiCo Magnet:

----The End----

Send Inquiry :

Products Category

Featured Products

Contact Us

Name: April Yang

Tel: 0086-1560-1120-906

E-mail: [email protected]

Add: No. 18, Sihai Road, BDA, Beijing, China

Whatsapp: 0086 1560 1120 906

Wechat: 0086 1560 1120 906

QQ: 1013104078